Top Stories

In response to a surge in U.S. construction, Peri USA has develoed a new formwork solution that caters to various size ranges for wall, column, and slab formwork

Three-model fixed and rotating range launched at ceremony in Changsha

Just how important will the next generation of engineers be for the built environment?

Transforming road construction is one of the biggest challenges, says Institute of Highway Engineering

Volvo Construction Equipment reveals its financial results for Q1, 2024

NEOM’s head of digital and IT on the Trojena project outlines the power of gaming technology that is revolutionising construction

Sponsored Content

The new specialist for layer processing in road construction

Machine uptime: paving the way to profit

Partner Content

The importance of keeping roadbuilding machines on the road

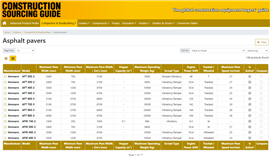

Construction Sourcing Guide

The comprehensive guide for buyers and users of construction equipment

The Construction Sourcing Guide is an invaluable tool for

industry professionals, containing information on over 9,000 products from over 240 equipment

producers and providers.

See a demo of how it works.

GO TO WEBSITE

Insights and analysis from the global construction industry

Contacts

Andy Brown

Eleanor Shefford

Mike Hayes

Simon Kelly