What US Army engineers found when they added graphene to cement

22 January 2024

Graphene molecular grid (Image: koya979 via AdobeStock - stock.adobe.com)

Graphene molecular grid (Image: koya979 via AdobeStock - stock.adobe.com)

The US Army has been exploring the potential of wonder material graphene when it comes to making stronger mortar and concrete for both military and civil applications.

Graphene, discovered in 2004, is a single layer of carbon atoms, bound in a hexagonal honeycomb lattice. Extracted from graphite, it is highly conductive, weighs very little, and has remarkable strength.

Introducing it to concrete could, in theory, address issues with low tensile strength and permeability. Its potential to increase the strength of concrete could also reduce the need for steel reinforcement, paving the way for a reduction in CO2 emissions.

New graphene study

Before the application of load to 0.02% (w/w) laboratory-generated graphene (LGG)-cement paste (Image: Graphene in Cementitious Materials/ERDC)

Before the application of load to 0.02% (w/w) laboratory-generated graphene (LGG)-cement paste (Image: Graphene in Cementitious Materials/ERDC)

But the use of graphene in cement and concrete is still in its infancy and there are hurdles to overcome – particularly when it comes to finding the correct graphene dosage, particle size, the speed of mixing, and how to disperse the wonder material through the concrete to achieve optimal strength.

That is what a US Army Engineer Research and Development Centre (ERDC) report published last month (December 2023) called Graphene in Cementitious Materials set out to achieve.

Researchers tested both commercial-grade graphene (CGG) and laboratory-generated graphene (LGG) to create small quantities of graphene-cement mixtures.

After mixing the graphene into standard Portland cement using a dispersant, the researchers cured the mixture in a fog room for seven, 14 and 28 days before performing compressive strength tests and chemical and microstructural analysis. The graphene-cement mixtures were compared to a reference cement mixture that contained no graphene.

Stronger cement...if the ingredients are right

What the researchers found was that it is possible to obtain graphene-cement pastes with higher compressive strengths than standard cement.

But that did rely on finding the correct dosage of graphene and achieving optimum dispersion of the material through the cement (the study found that MasterGlenium 7920 concrete admixture was the most effective surfactant for this).

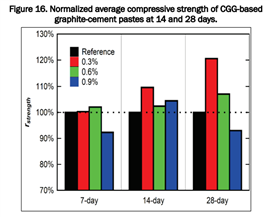

For example, a 0.3% dosage of commercial-grade graphene performed the best, showing a consistent increase in its average compressive strength, from just over 100% of normal Portland cement after 7 days of curing, just under 110% after 14 days, before rising again to over 120% after 28 days.

A 0.6% dose of CGG-based graphite cement paste showed a marginal improvement over time too, but a 0.9% dose performed less well in strength tests than standard Portland cement after both 7 and 28 days.

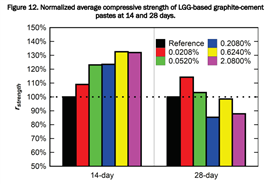

When it came to LGG cement mixtures, all graphite-cement mixtures performed better in strength tests after 14 days of curing. But their performance tailed off after 28 days of curing.

Source: Graphene in Cementitious Materials/ERDC

Source: Graphene in Cementitious Materials/ERDC

The results showed how important good dispersion of graphene through the cement is, as well as getting the correct dosage of graphene right. Getting those variables wrong risks multiple layers of graphene coming together. And when layers of graphene do agglomerate, the forces that hold them in place are weak and can end up compromising the strength of the cement mixtures.

The report noted: “These findings point out the importance of achieving optimum graphene dispersion in the cementitious media that is determined by the type of dispersant, the rate of high-shear-rate mixing, along with graphene type, size, and dosage rate.”

Next steps

Nonetheless, the researchers indicated that they see a bright future for graphene-enhanced concrete.

The report said, “One can expect to see significant improvements in graphene-concrete over conventional concrete in tensile and flexural applications where the tensile strength and Young’s modulus of graphene will be utilized better.”

Source: Graphene in Cementitious Materials/ERDC

Source: Graphene in Cementitious Materials/ERDC

The US Army engineers now hope to continue their research, examining the impact of fine and coarse aggregates on the behaviour of graphite-concrete materials.

“Exploring the opportunities in the use of graphene will allow for better-performing structures in military engineering under blast and penetration situations. Further investigation of graphene in cementitious matrices will facilitate adoption of GRM for military construction, warfighter support, fighting climate change, and use in our nation’s vast civil works infrastructure,” the report concluded.

Read ERDC’s full report, Graphine in Cementitious Materials.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM