Industry resources are scarce, embracing circularity will help

02 February 2024

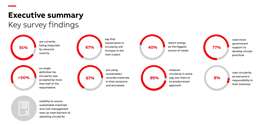

An alarming new report from ABB says 91% of industrial businesses are struggling with resource scarcity, and the Swiss-based corporation is calling for systematic circularity

A US arm of Swedish-Swiss technology company ABB – ABB Motion – has released a report that reveals that nearly the entire global industrial sector is grappling with access to needed resource.

The report, entitled Circularity: No Time to Waste, reported that, “Raw materials (39%) are seen as the scarcest resource, followed by labor (35%), and electronic components (33%).” It added that, “Resource scarcity has led to increased costs for 39% of businesses, as well as supply chain disruption for 39% and slowdowns in production capacity for 29%.”

The survey received more than 3,000 responses from 12 different countries.

“Despite energy being an increasingly scarce resource, over 40% reported it as their biggest source of waste,” added ABB.

And no one country is created equal regarding what it’s wasting or how it’s wasting it.

“Geographically, waste patterns vary significantly, with distinctions such as high energy waste in Canada and the UK, elevated raw material waste in India, and increased water waste in France, all underscoring the importance of tailored strategies in different regions,” said ABB.

Responding with circularity

The report encouraged businesses to embrace and invest in circularity practices guided by three pillars: adopt a holistic approach to circularity, instil a sense of responsibility at every level of the organisation, and embrace new technologies and foster collaborations to advance circular practices.

“The findings demonstrate that businesses now view circularity through a comprehensive lens that surpasses conventional recycling practices,” said ABB Motion president Tarak Mehta in the report. “This broader perspective encompasses waste reduction, sustainable design, and the development of resource-efficient processes.”

One major shortcoming ABB identified in circularity approaches is a lack of cohesion in the practice and basic agreement, even, on what the term means.

“There is still some way to go in establishing a single, universally accepted understanding,” stated the report. “In fact, no single definition in our survey was accepted by more than half of the respondents.”

And yet, 99% of respondents said they were measuring circularity within their business in some way.

“The disparity arises from different interpretations of definitions and measurement criteria for circularity, highlighting a potential gap between perceived success and actual implementation,” explained the report.

“While awareness is expanding, the question remains: is it progressing swiftly enough?”

While most understand that recycling and efficiency are core components toward obtaining circularity, ABB notes a more acute definition will be necessary to help businesses focus on efficiency and eliminate wasted time and (already scarce) resources.

“This includes embracing sustainable sourcing, resource-efficient operations, and responsible end-of-life practices; the move from a ‘take, make, dispose’ model to a circular economy aims to minimize waste,” stated the report.

Initial costs are barrier despite promise of savings

The survey went on to expose that, although businesses are aware of the benefits of circularity, many have had difficulty spending the high initial costs to restructure or plan for a circular transition.

“While embracing circularity holds the potential for long-term cost benefits, the perceived barrier of cost management is considered the most challenging,” stated the report. “Implementing circular practices may involve initial expenses, making it a difficult hurdle for businesses to overcome.”

Still, ABB says the right investments in circular approaches will almost always lead to long-term savings and industry-wide benefits.

“The long-term advantages, such as addressing resource scarcity and reducing waste, highlight the need for investment in circular approaches. This underscores the importance of continuous development and affordability of sustainable technologies and resources,” stated the release.

Every region and sector is different, though, ABB noted.

“It can also be argued that there is no clear outlier in terms of the most difficult challenge,” the company stated. “For instance, Chinese respondents, as well as those in the oil and gas industry, rated limited circular technologies as the most difficult challenge. This demonstrates that, although cost is a common obstacle, individual industries and businesses face their own unique circumstances and challenges when it comes to adopting circularity.”

Resource scarcity is a compounding issue

In simple terms, limited access to needed materials will inflate the cost of those materials, which ultimately has a net negative effect on the entire industry.

In regions or timeframes where construction and building activities are down, scarcity may not have too significant an effect on prices but, in regions where activities are booming, the issues could spiral.

“This is likely to get worse as markets grow – unless businesses act,” said the report. “For example, Chinese respondents identified the scarcity of raw materials as the most significant issue (46%). And yet, the manufacturing market in China is projected to grow by roughly 4% between 2024 and 2028, resulting in a market volume of US$5.82 trillion in 2028 (according to Statista). To sustain this growth, material efficiency must be improved – and this is possible through enhanced circularity.”

Examples of circularity in action

In addition to encouraging single businesses to invest in their own circular practices, the report offered at-a-glance solutions from across the globe.

“While Europe leads in policy maturity, North America and the rest of the world are also taking significant steps,” said ABB. “The state-level approach in the US, like California’s legislative package and investment in recycling systems, reflects a growing commitment to circularity. Right to repair policies in certain US states will likely motivate companies to provide the same repair information to all US customers.

“Canada’s ban on single-use plastics and Latin America and the Caribbean’s regional strategies illustrates a growing global tide of circular economic principles.

“India is also taking positive steps in implementing different rules to avoid plastic, metal, and e-waste. Eleven government committees have also been formed to drive the circular economy in their respective areas.

“In the Asia-Pacific region, countries like China, Japan, and South Korea are advancing their own circular economy policies, with China promoting circularity as a national political objective – for example, with its Circular Economy Promotion Law.

“In Africa, measures such as the National Action Plan for Sustainable Consumption and Production in Egypt and the African Development Bank’s stance on coal financing demonstrate a burgeoning recognition of circular economy benefits.

“Therefore, the global shift toward circular economies is becoming increasingly legislated, systematized, and integrated into the fabric of international trade and manufacturing standards, fostering a more resilient and sustainable global economy.”

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM