How is new technology improving crane efficiency?

16 January 2023

New technology recently launched to the crane market can improve the efficiency of fleet management, train future operators safely and use data to ensure the success of future operations. Niamh Marriott reports.

Software is being used to improve the efficiency of fleet management.

Tadano partners with HeavyGoods on software for load securing. Photo: Tadano

Tadano partners with HeavyGoods on software for load securing. Photo: Tadano

Japanese crane manufacturer Tadano has partnered with HeavyGoods, a software developer for swept path simulation, axle load calculation, and load securing.

The online software offers benefits for crane companies, explains HeavyGoods managing director Susann Beyersdorfer, “With our HeavyGoods app, users can simulate crane driving manoeuvres directly online on Google Maps or on their own drone aerial imagery, PDF site drawings, or official survey maps. They can then view the simulations as swept paths in video format.”

“Our customers are often faced with the challenge of how best to navigate tight spaces to get their cranes onto the construction site.

“In these cases, HeavyGoods is a huge help when it comes to selecting the best route,” says Martin Lottes, team leader of concept design at Tadano.

For these reasons, the crane manufacturer has decided to enter into a partnership with the Dresden, Germany-based software developer under which all data for its entire range of all terrain cranes is loaded into the HeavyGoods catalogue.

The benefit for users is that they don’t have to manually enter extensive crane datasets. Instead, they can select preloaded datasets that have been verified by the crane manufacturer.

If they are already HeavyGoods customers, they can access the Tadano data right away and use them for their swept path simulations at no additional cost.

Simulation software

A final benefit is for the operators of Tadano cranes who can simulate all tight spots along the route from the crane’s starting location to the setup location on the construction site, the company says.

This increases planning certainty and eliminates time-consuming detours and turning maneuvers.

“Never again will our customers get their Tadano cranes stuck in tight spots en route,” says Lottes.

The software also streamlines collaboration with government agencies with its professional driving-manoeuvre videos and ability to generate test reports complete with axle load information and documented load securing for heavy haulage operations.

Crane rental platforms

The crane industry seems to be finally embracing this digital change and the advantages that online services can provide.

MyCrane’s app verifies images and data about cranes available for rent. Photo: MyCrane

MyCrane’s app verifies images and data about cranes available for rent. Photo: MyCrane

Dubai-based digital crane rental platform MyCrane has launched a new free inspections app which the company says will allow its customers to rent lifting equipment with confidence.

Available with Apple and android, the app helps prevent fraud and reduces risk by digitalising the process of the crane rental inspection.

The app, available in more than 35 languages, makes use of artificial intelligence to verify data such as location of the crane and the authenticity of its registration documents.

Images of the crane can be uploaded with key data about the equipment. Only live image and video recording can be accepted, while in-app fraud detection and recognition is another feature.

According to MyCrane, the new App is particularly useful where clients impose the condition and maximum age of equipment, or where clients have specific requirements around inspection.

Crane condition

Customers can make use of the MyCrane app to review the condition of the equipment, prior to placing an order.

“Our new app is a tool that offers a high level of transparency for our customers, reassuring them that the proposed equipment is as described, and helping to minimise disputes,” says Andrei Geikalo, founder and CEO of MyCrane.

“Crane rental providers will also find the app useful,” he continues. “In the case of bare rentals, for instance, our app may provide proof of discrepancies between the outgoing inspections and incoming inspections when the equipment is confirmed off-rent and being returned to the crane provider, because it will be so simple to verify the condition of the equipment.

Crane fleet management

At the Bauma 2022 trade show Liebherr unveiled its own fleet data management solution for its mobile and crawler cranes.

At Bauma 2022, Liebherr unveiled its own fleet data management solution. Photo: Liebherr

At Bauma 2022, Liebherr unveiled its own fleet data management solution. Photo: Liebherr

In addition to the machine’s location, the system displays a range of additional real-time data, such as the fuel consumption, the current wind speed, the weight of the load on the hook and even when the crane’s next service is due.

Customers can also use the system to generate custom reports for specially defined construction sites, such as the fuel consumption or carbon dioxide emissions.

Many new cranes now have the necessary wireless modem on board as standard. Cranes in the field can be easily retrofitted in the future, Liebherr says.

Liebherr product manager Wolfgang Boos explains, “It is important to us not to display arbitrary data just because a corresponding sensor is installed. We want to provide the customer with data that helps them manage their machine fleet and thus operate it as economically as possible.”

The entire system is based on the “MyLiebherr” customer portal. Having registered their cranes in the portal, customers can then download operating instructions or order spare parts, too.

Operator training

New technology can be used to enhance the training of operators, and potentially encourage new young people to become a part of the crane industry.

CM Labs Simulations’ mobile training centre. Photo: CM Labs Simulations

CM Labs Simulations’ mobile training centre. Photo: CM Labs Simulations

Training simulator developer CM Labs Simulations has released a mobile training centre for North America for flexible training.

The centre can offer an on-site presence that reduces team displacement and job site disruption. For community colleges and vocational schools, it can multiply training locations and provide access to markets that were previously out of reach or too remote.

The gooseneck trailer accommodates one or two Vortex simulators from CM Labs, as well as the Instructor Operator Station, from which trainers can monitor, assess, and report on training progress. The trailer can be hitched to a vehicle for transport or set up as a standalone station.

The all-season training environment is equipped with a generator, insulated HVAC cooling, and heating. Included is a breaker panel with a manual power switch to connect to a diesel generator or local grid, Ethernet, wi-fi, and LED lighting with three switch zones.

“Bringing training and recruitment to where it’s needed most can be a cost-effective strategy,” says Lisa Barbieri, VP of marketing and product management at CM Labs.

“The combination of our best-in-class-simulators and high-impact messaging gives our customers the means to position themselves leaders in operator safety training and assessment.”

Software update

Earlier in 2022, the company issued a new software release for its construction simulator training packs. This new release is designed to boost trainee engagement by featuring heightened visuals, greater training immersion, and increased learning retention.

CM Labs said the result is faster, more efficient operator skills development.

The new graphics provide a level of depth and realism that, in conjunction with CM Labs’ machine simulation, further reduces the gap between classroom training and the worksite.

The new release can be experienced across CM Labs’ fleet of construction training packs.

The lifting simulations include a luffing jib tower crane, flat top tower crane, crawler crane, rough terrain crane, boom truck, and forklift.

The earthmoving simulations consist of the excavator, dozer, wheel loader, backhoe, and motor grader. The forester and harvester make up the company’s forestry simulation training packs.

“The current boom in construction jobs is highlighting the importance of closing the skills gap,” says Barbieri. “That’s why we are focused on providing the most immersive learning experience to deliver the world’s best training outcomes.”

Camera systems for cranes

It’s not just software being launched for the industry. Several new hardware devices aim to improve the safety and efficiency of crane operations, including cameras.

Video cameras on cranes can play a key role in ensuring operator safety and preventing on-site damage, saving both money and time.

French specialist supplier of safety solutions for jobsites AMCS Technologies has a new video camera, the Cam 61. It is aimed at construction and industrial applications.

AMCS Technologies has a new video camera. Photo: AMCS Technologies

AMCS Technologies has a new video camera. Photo: AMCS Technologies

“We have made this development a strategic asset in this worldwide context of a components shortage, making sure to have sufficient stocks to meet our customers’ demands,” says Mohamed Chettibi, AMCS Technologies CEO.

“We wanted to develop a sustainable solution and control production at all stages and also open new market opportunities.”

Cam 61 offers increased safety and greater productivity by allowing work to proceed significantly faster and with greater precision, while reducing stress on operators, says the company.

Wireless hook crane camera

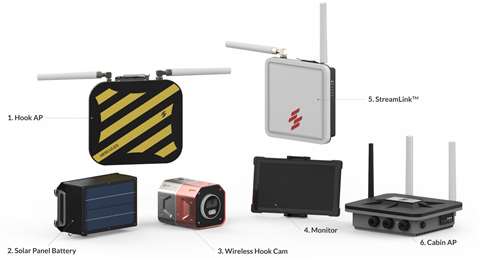

Another camera this time for the hook comes from Taiwan-based construction technology company Scarlet Tech. The Hercules wireless hook crane camera, which provides real-time footage in 2K.

The piece of monitoring equipment is made for all types of heavy-duty construction cranes. It records and transmits live footage of the surrounding area below the hook and other areas of the construction site.

Scarlet Tech has released a new camera for cranes which provides real-time footage in 2K. Photo: Scarlet Tech

Scarlet Tech has released a new camera for cranes which provides real-time footage in 2K. Photo: Scarlet Tech

The company said it’s ideal for safety professionals working on constructions sites to overcome blind spots and identify hazards.

Real-time data

“Hercules is the first-of-its-kind in the market,” says Dr David Huang, co-founder and managing director at Scarlet Tech. It uses wireless technology to provide a clean visual and audio feed.

Huang adds, “In many complex construction sites with high-rise buildings or in underground construction, crane operators often have difficulty in getting a clear and unobstructed view from below the hook.”

The camera has a dual-powered lithium-ion battery that can last up to 40 hours. The company also says it has low latency and provides real-time video feeds so operators can make informed decision quickly.

The options for improving the crane operating experience, from training operators to digital aids for fleet management, are endless as the industry leads the way with the very latest technology.

This article originally featured in the December edition of International Cranes and Specialized Transport.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM