How is construction becoming more sustainable?

06 September 2022

The world is waking up to the importance of sustainability, as is the construction industry. Andy Brown looks at what the sector is doing to cut emissions and why construction has actually been on a sustainability drive for decades.

When people around construction mention sustainability there’s a danger that some who have been in the industry for a while might roll their eyes at what is undoubtably one of the ‘buzzwords’ of the sector.

Sustainable practices in the construction industry has increased steadily in recent years.

Sustainable practices in the construction industry has increased steadily in recent years.

However, the truth is that construction has been striving for sustainability ever since the first structure was erected, it is just that it was called something different – efficiency or productivity. Any company that is working to become more efficient is also working on being more sustainable.

Dietmar Grimm is VP of Corporate Strategy and Sustainability Solutions at Trimble and is fairly new to the world of construction, having previously worked on sustainability projects with companies such as Amazon and Microsoft.

He says that when he joined Trimble there were some in construction who were doubtful that the sector was ready to embrace sustainability and wished him good luck, thinking that he would need it.

Grimm says that he made the point to these people, as he does to all in construction, that sustainability, “is not this big, scary thing that you might think it is. It is something that you already do, and you already know how to do – driving efficiency and productivity.”

He adds that the key for sustainability targets to be hit is data. Having data about projects means that information on how many machines were used (and for how long) is available, as well as information on exactly how much material was moved and from where.

Large numbers of construction firms have signed up to science-based targets to reduce emissions. In order for them to verify what they have been doing, hard data is required.

Grimm says that one of the advantages that Trimble has is helping these companies in “connecting the physical and digital worlds.”

How is AI being used to decarbonise construction?

Data and, specifically, Artificial Intelligence (AI), is at the heart of a new company that has ambitious plans to decarbonise the construction industry, Carbon Re.

Formed in ‘lockdown’ during the Covid-19 pandemic in 2020 the company – which is looking to double in size soon due to new investment – looks to reduce emissions in existing industrial processes, such as in cement production.

The company’s first product is aimed at optimising cement production and there are plans to move into the steel and glass industries in the future. Sherif Elsayed-Ali, co-founder of the company, says that they can, “reduce emissions from existing cement plants by 8-10% and, as a consequence of this, there is a reduction in costs as we are optimising fuel use.”

Carbon RE uses AI connected to hundreds of data points to help cement factories reduce their emissions. (Photo: Carbon RE)

Carbon RE uses AI connected to hundreds of data points to help cement factories reduce their emissions. (Photo: Carbon RE)

In relation to the AI that the company use, Elsayed-Ali says that the basic principles were there but the company had to do a lot of work; there was nothing that did the specific tasks they required.

“The biggest challenge in AI is applying it to a specific problem in a specific domain,” he says. “Regarding the optimalisation of cement we had to do this from scratch, nobody else had done anything.”

One of the reasons why this hadn’t been done previously is that AI requires a vast amount of data to work, and it is only in the last few years that this data has become available.

The second is its complexity – the AI evaluates information from hundreds of data points to make recommendations. Elsayed-Ali says that to get AI to be able to do this requires “top tier machine learning people.”

What is the cost of electric machinery?

Data is undoubtably key in the sustainability drive of the industry and so, for some, is the transition to electric equipment. There are electric excavators, drilling rigs, cranes and more in the sector and, while the majority of OEMs are officially adopting a ‘power neutral’ stance there is no doubt that many have backed electric equipment as the future.

However, this approach is not without problems – one of the main ones being cost. “Going electric is the solution most favoured, but almost everything about it is cost intensive,” comments industry expert Carl-Gustaf Göransson, the former president of construction at Case.

“And not just the machines themselves, but other factors, such as the need to develop widespread charging infrastructure, availability of power at peak hours and facilities for recycling and re-use of spent batteries.”

Alan Berger, who has previously headed up technology departments at Volvo CE and Case adds that, “To put things into perspective, the cost of manufacturing electric powered construction machinery is at least double that of diesel, making them (due to pass-on costs) prohibitively expensive for many customers to justify making the change.

“Construction needs a dose of the treatment given to the car industry, where governments’ stimulus packages have lowered the price to the end user, and thereby accelerated the transition to more sustainable fleets on the roads.”

Why is sustainability important in construction?

In an interview given last year to International Construction, Victoria Burrows, Director, Advancing Net Zero, World Green Building Council, said that the drive to sustainability needs to happen long before any work begins.

“Improving sustainability in construction starts in the design phase long before the first shovel hits the ground,” she said. “However, construction companies play a significant role in translating those designs into reality.”

Sustainable construction is evolving at a fast pace, requiring companies to stay up to date with the latest practices, materials and technologies. By finding ways to reduce waste, avoiding damage and curbing rework, projects become leaner and more efficient.

Integrated project delivery and lean construction practices encourage efficient processes and outcomes, and help meet sustainability goals of owners, designers and contractors.

Alan Berger has previously headed up technology departments at Volvo Construction Equipment and Case.

Alan Berger has previously headed up technology departments at Volvo Construction Equipment and Case.

Companies can improve sustainability by developing and implementing construction policies and documentation practices that explicitly state why, how, when, what and by whom things will be done.

By planning sustainable practices across entire processes, ‘green’ methods become normalised.

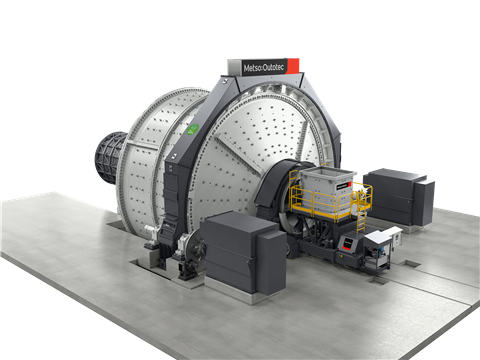

A large number of companies related to construction have integrated sustainability into more and more parts of their business, such as Metso Outotec.

The company has published a Sustainability-Linked Finance Framework that continues to integrate its sustainability strategy into its financing arrangements.

The company says that sustainability is a strategic priority and that it is embedding it across all areas of the business, including linking sustainability performance with the terms of financing.

“Our commitment to net-zero CO2 by 2030 as well as growing our Planet Positive sales can now be tied to our financing arrangements,” says Marius Verwoerd, VP, Sustainability, Metso Outotec.

“This is a strong signal to everyone, including our customers, suppliers and capital markets, that we are truly ‘walking the walk’ with sustainability.”

Sustainable infrastructure projects

Sustainability is a mega trend around the world, although some geographical areas are investing more heavily into it. Stephane Asselin, chief executive, Aurecon Asia, says, “Asia is charting its path towards a greener future, which brings with it growing demand for sustainable and resilient infrastructure.

“More clients and investors are increasingly expecting a stronger sustainability proposition to be incorporated into their projects right from the outset.”

Despite this, Asselin says that it isn’t always easy to get financing for ‘green’ projects. “Given that governments have competing priorities, financing for sustainable infrastructure can be a challenge.

Nonetheless, there are also new green financing windows opening like the World Bank’s City Climate Finance Gap Fund, which aims to provide over €4 billion of investment to support the development of climate-smart urban infrastructure.”

Aurecon has been appointed consultant for two floating solar farms in Singapore. (Photo: Aurecon)

Aurecon has been appointed consultant for two floating solar farms in Singapore. (Photo: Aurecon)

There’s no doubt that there are lots of different ways for the industry to become more sustainable but, ultimately, government regulations are a vital driver of change. “For construction to become more sustainable a number of stars need to come into alignment,” comments Carl-Gustaf Göransson.

“By far the biggest of these is for national governments to appreciate the gravitational pull they have, and to initiate stimulus and legislation programs that encourage (or even force) contractors and construction companies into investing in cleaner technology and infrastructure. Without this spur to demand we fear this still-conservative industry will change too little, too late.”

In certain countries there are government policies that push green construction, but it is by no means widespread. This is slowly happening in the US, where President Biden’s US$1.3 trillion infrastructure bill has money set aside for certain environmental initiatives, such as US$7.5 billion to build the first national network of EV chargers in the US.

It is also thought that contractors that meet certain environmental stipulations will have a better chance of winning contracts.

Much more of a lead from government is needed but, for now, an industry looking to increase its productivity can have a real impact on sustainability. “If you can make things last 30 years longer, there’s a whole significant reduction in carbon emissions.

“There might be higher upfront costs, but longer term, there are savings financially and in carbon in not having to rebuild it,” says Trimble’s Grimm.

Using AI to cut emissions

Increasing productivity is the way that Carbon Re’s AI can reduce emissions in cement factories – more efficiency means less fuel used and equals time and CO2 savings. The AI gives recommendations to factory operators, but doesn’t implement them automatically.

Buffy Price, co-founder, says the industry’s reaction has been, “Very positive. Our pipeline of trials is full… some of the top ten global players have signed up to do trials with us. Rising fuel costs has been a big driver as well as the incoming emissions trading schemes and taxes in the EU…. you see what is happening with the climate, we need to act now.”

The use of AI to reduce carbon emissions in industrial processes like cement could prove to be invaluable as the industry reduces emissions.

Metso Outotec calls itself a ‘a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally’. (Photo: Metso Outotec)

Metso Outotec calls itself a ‘a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally’. (Photo: Metso Outotec)

There are lots of ways the sector can increase sustainability and become more efficient. As a first step, focusing on so called ‘low hanging fruit’ makes sense.

“In the near term, the easy wins are focusing on how can we make sure we’re using all of our machines as efficiently as possible? Those are easy wins,” says Grimm.

“We need as much carbon reduction in these next ten years as possible and we’re not going to electrify everything in the next ten, 20, 30 years.

“There’s a whole transition that’s going to happen, including hydrogen and other alternative power, but it is going to take time.”

Until it does – and even when it does – increasing efficiency and productivity will remain vital.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM